Dažnos problemos ir jų sprendimai gaminant WPC duris ekstruzijos būdu

2025

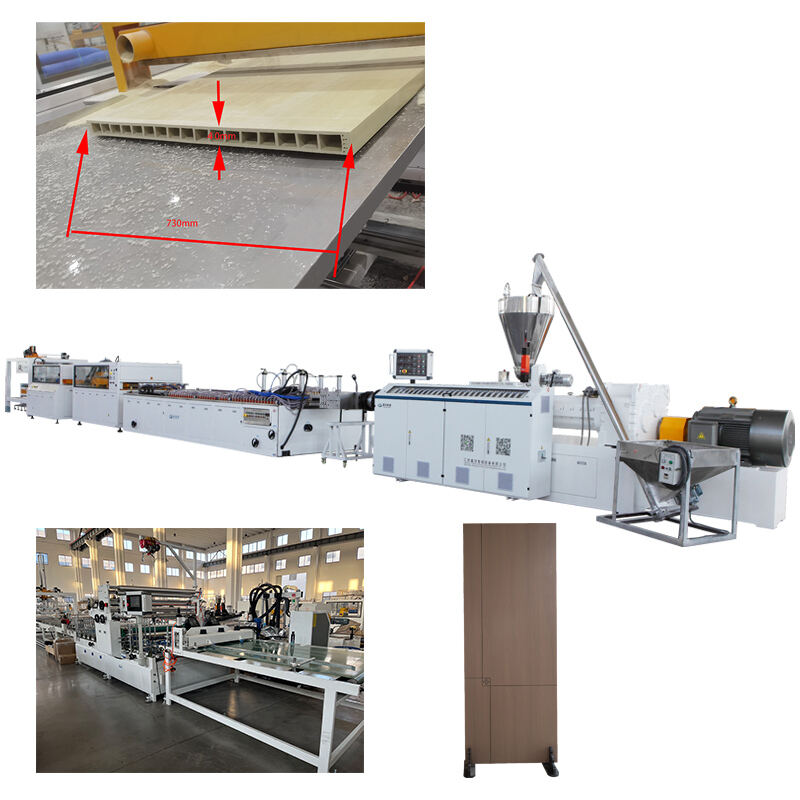

Xinhe Machinery turi tikrų durų plokščių gamybos klientų šalyse, tokiose kaip Saudo Arabija, Vietnamas, Jordanija ir Irakas. Mes teikiame techninę pagalbą nuo žaliavų iki gatavos produkcijos, padedant klientams augti nuo nulio iki daugiau nei dvylikos durų plokščių ir rėmų gamybos linijų. Turime didelę patirtį durų plokščių gamyboje. Apibendrinome dažnines problemas ir jų sprendimus WPC durų ekstruzijos gamyboje, kurios daugiausia susijusios su trimis aspektais: procesu, įranga ir medžiagomis:

I. Proceso klausimai

1. Lipnumas

Priežastys: PVC dervos silpna šiluminė stabilumo savybė, netinkamas stabilizatorių parinkimas formulėje, trimerių skaidiklių (trys skaidikliai skirtingu laiku veikia skirtingai, todėl visi trys turi būti tinkamai parinkti) santykio netinkamumas arba neprotingas technologinių parametrų valdymas (pvz., temperatūra, sraigto greitis ir mirgalio slėgis).

Sprendimai: optimizuoti formulę, parinkti tinkamus stabilizatorius ir tepalus, kontroliuoti žaliavų drėgmę ir mažo garumo turinį, taip pat sureguliuoti technologinius parametrus į protingą ribą.

2. Paviršiaus defektai

Pasireiškimai: Prastas blizgesys, nepakankamas paviršiaus kietumas, brūkšniai, įdubimai, tamsios/šviesios juostos, įtrūkimai ar priemaišos.

Sprendimas: Sureguliuokite procesą, kad užtikrintumėte stabilius parametrus, tokius kaip temperatūra ir slėgis.

3. Traukimo greičio ir ekstruzijos greičio neatitikimas

Poveikis: Sukelia netolygų sienelės storį, nuosekliai nevienodas tolerancijas ir netgi paveikia fizinio-mechaninius savybes.

Sprendimas: Dvikovščiuose ekstruderiuose, kai sienelės storis <1 mm, sraigto apsukos turėtų būti 20–25 aps./min, o traukimo greitis – 3–4,5 m/min; kai sienelės storis >2 mm, sraigto apsukos turėtų būti 15–20 aps./min, o traukimo greitis – 0,6–1,5 m/min.

II. Įrangos problemos

Per didelis formos galvutės slėgis

Poveikis: Veda prie lėto ekstruzijos greičio, paveikdama išvestį.

Sprendimas: Optimizuokite mirgalio galvutės projektavimą ir sureguliuokite sraigtinio greitį bei mirgalio galvutės slėgį.

Nepakankamas aušinimas

Poveikis: Profilio deformacija ir paviršiaus bangavimas.

Sprendimas: Naudokite oru aušinimą arba purškimo vandens baką aušinimui, kad profilis atvėstų iki kambario temperatūros.

3. Nepakankamas ekstruzijos kiekis

-

IMPACT : Nestabilus produkto kokybė, didelis broko lygis.

-

Sprendimas : Pasirinkite skirtingus ekstruderius skirtingo pločio durelių skydams; paprastai naudojamas 92/188 ekstruderis. Sumažinant mašinos kainą, durelių skydams siauresniems nei 800 mm galima naudoti 80/156 ekstruderį; jei plotis didesnis nei 900 mm, būtinai reikia naudoti 92/188 ekstruderį.

III. Medžiagos problemos

Per didelis medžio miltelių kiekis

- IMPACT : Lemia prastą gaminio atsparumą ir lengvą lūžimą.

- Sprendimas : Kontroliuokite medžio miltelių kiekį, kad užtikrintumėte gerą žaliavų plastifikaciją ir išvengtumėte nešvarumų. „Xinhe Machinery“ nustatė, kad optimalus medžio miltelių kiekis yra 5 %–10 %, o geriausia – visai nepridėti medžio miltelių. Priežastis, kodėl tai vadinama WPC durimis, yra ta, kad jos iš pradžių buvo sukurtos medžiui perdirbti. Šiuo metu medžio milteliai yra santykinai reti, todėl juos nepridedant pasiekiama geriausia išeitis, taip pat sumažinant gamybos kaštus.

Medžio miltelių blukimas

- Priežastis : Dėl aplinkos veiksnių, tokių kaip temperatūra, drėgmė ir šviesa, gali blukti derva, pigmentai ar pačių medžio miltelių spalva.

- Sprendimas : Pradiniame etape cheminiu būdu nuvalykite spalvą iš medžio miltelių, tada nuspalvinkite ją pigmentais; arba pasirinkite tamsius pigmentus ir šviesą sugeriančias medžiagas (pvz., anglies juodąją) slėpimui.

IV. Kiti klausimai

1. Prasta vidaus ertmės formavimosi kokybė

-

Priežastis: Netinkamas formos konstrukcijos projektavimas ar technologiniai parametrai.

-

Sprendimas: Optimizuokite formos projektavimą ir sureguliuokite technologinius parametrus.

2. Mažas statinis slėgio atsparumas

-

Priežastis: Medžiagos formulavimo arba proceso problemos.

-

Sprendimas: Optimizuokite formulavimą ir koreguokite proceso parametrus.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ